Unlock Global Opportunities with Our Comprehensive Solar Panel Guide

Introduction: Navigating the Global Market for solar panel

In an era where sustainability is not just a trend but a necessity, the solar panel market has emerged as a pivotal sector for international B2B buyers. As countries across Africa, South America, the Middle East, and Europe strive to reduce their carbon footprints and meet renewable energy targets, the demand for solar energy solutions is soaring. This guide serves as an essential resource for businesses looking to navigate the complexities of sourcing solar panels and related technologies.

Understanding the global solar panel market is crucial for making informed purchasing decisions. With a myriad of suppliers, technologies, and regulatory landscapes, buyers face the challenge of identifying quality products that align with their specific needs and sustainability goals. This comprehensive guide will explore key market dynamics, highlight innovative technologies, and present actionable insights to help buyers strategically assess their options.

Through this resource, we empower businesses to streamline their sourcing processes, mitigate risks, and ultimately enhance their competitive edge in the renewable energy landscape. Whether you are looking to invest in large-scale solar projects or seeking to incorporate solar solutions into your operations, this guide equips you with the knowledge to make informed decisions that drive value and promote environmental stewardship. Engage with us as we delve deeper into the opportunities and challenges that define the global solar panel market.

Understanding solar panel Types and Variations

Monocrystalline Solar Panels

Monocrystalline panels are recognized for their high efficiency and sleek black appearance, which is due to the use of single-crystal silicon. They typically achieve efficiencies ranging from 15% to 22%, making them suitable for applications where space is limited, such as commercial buildings and utility-scale projects. Their longevity and performance under various environmental conditions make them a popular choice, despite a higher upfront cost. For B2B buyers, investing in monocrystalline panels can lead to significant energy savings over time.

Polycrystalline Solar Panels

Polycrystalline panels are manufactured using multiple silicon crystals, resulting in a speckled blue appearance. They are generally less expensive than monocrystalline panels and have efficiencies ranging from 13% to 16%. This makes them an attractive option for residential installations and larger commercial applications where budget constraints are a primary concern. While they offer a lower efficiency and space utilization compared to their monocrystalline counterparts, their cost-effectiveness can provide a reasonable return on investment for businesses.

Thin-Film Solar Panels

Thin-film solar panels are characterized by their lightweight and flexible design, which allows for installation on various surfaces, including curved structures. They perform well in low-light conditions, making them suitable for applications like building-integrated photovoltaics and portable solar solutions. However, their efficiency is typically lower than crystalline panels, requiring more space for the same energy output. B2B buyers looking for versatile solutions may find thin-film panels advantageous, especially in specific architectural designs.

Bifacial Solar Panels

Bifacial solar panels are engineered to capture sunlight from both sides, enhancing their energy yield. They are particularly effective in large-scale solar farms and rooftops where reflection from surrounding surfaces can be harnessed. While they come with a higher initial investment, the potential for increased energy production can justify the cost in long-term projects. B2B buyers should consider bifacial panels for projects that can leverage their unique dual-sided design to maximize efficiency.

Building-Integrated Solar Panels

Building-integrated photovoltaics (BIPV) are designed to replace traditional building materials, such as roofing tiles and facades, seamlessly integrating into the structure. This innovative approach not only provides energy generation but also maintains aesthetic appeal. While the initial costs can be higher, the dual-purpose functionality of BIPV systems makes them ideal for new constructions and retrofitting projects. For businesses focused on sustainability and energy efficiency, BIPV offers a compelling solution that meets modern architectural demands.

Key Industrial Applications of solar panel

Detailed Applications

Agriculture: Solar-Powered Irrigation Systems

In regions where water scarcity is a challenge, solar-powered irrigation systems provide a sustainable solution. By harnessing solar energy, farmers can operate pumps that draw water from underground sources or nearby bodies of water, significantly reducing dependence on fossil fuels. This application not only lowers operational costs but also ensures that crops receive adequate water, leading to improved yields. B2B buyers should focus on sourcing systems that are compatible with existing infrastructure and evaluate local suppliers who understand the specific agricultural needs of the region.

Manufacturing: Solar Energy for Production Facilities

Manufacturing plants are significant energy consumers, making solar energy a viable option for reducing operational costs. By integrating solar panels into their energy supply, manufacturers can decrease reliance on grid electricity, which is subject to price fluctuations. This transition not only lowers energy bills but also supports corporate sustainability goals, enhancing brand reputation. Buyers should consider the scalability of solar installations and the long-term maintenance support offered by suppliers to ensure a reliable energy supply.

Telecommunications: Solar-Driven Communication Towers

In remote and underserved areas, solar-powered communication towers can ensure that telecommunication services remain operational without interruption. These towers rely on solar energy to power antennas and related equipment, providing a reliable communication link even in areas where grid electricity is unavailable. For B2B buyers, it’s crucial to assess the geographic location of installations and understand local regulations regarding tower construction and energy use to ensure compliance and operational success.

Mining: Solar-Powered Mining Operations

The mining industry is increasingly adopting solar energy solutions to power operations, reducing reliance on diesel generators and other fossil fuels. By utilizing solar panels, mining companies can significantly cut fuel costs while minimizing their environmental impact. Additionally, solar energy can be used to power remote camps and facilities, ensuring a sustainable energy supply. Buyers should investigate long-term energy storage solutions and the compatibility of solar systems with existing mining equipment to maximize efficiency.

Hospitality & Tourism: Solar Energy for Resorts and Hotels

In the hospitality sector, resorts and hotels are increasingly turning to solar energy to enhance guest experiences while reducing operational costs. Solar panels can provide energy for heating, cooling, and lighting, contributing to lower utility bills and promoting eco-friendly practices. This not only attracts environmentally conscious travelers but also helps establishments achieve sustainability certifications. B2B buyers should analyze the energy efficiency of existing systems and consider how new solar installations can integrate with current operations to enhance overall performance.

Strategic Material Selection Guide for solar panel

When selecting materials for solar panels, understanding the unique properties, advantages, and disadvantages of each material is crucial for B2B buyers looking to make informed decisions. Below are analyses of four common materials used in solar panels: Monocrystalline Silicon, Polycrystalline Silicon, Thin-Film, and Bifacial Solar Cells.

Monocrystalline Silicon

Properties:

Monocrystalline silicon is made from a single crystal structure, which gives it a high level of purity and efficiency. It typically has an efficiency rate of around 15-22%.

Pros:

- High Efficiency: Monocrystalline panels are among the most efficient on the market, making them ideal for space-constrained installations.

- Longevity: These panels have a longer lifespan, often exceeding 25 years.

- Aesthetic Appeal: The uniform dark color and sleek appearance make them visually appealing.

Cons:

- Cost: They are generally more expensive than other types, which can be a barrier for some projects.

- Performance in High Temperatures: While they perform well in low-light conditions, their efficiency can decline in high temperatures.

Application Impact:

Monocrystalline panels are particularly beneficial for residential and commercial installations where space is limited and aesthetics are important. They offer a strong return on investment over their lifespan.

Polycrystalline Silicon

Properties:

Polycrystalline silicon is made from multiple silicon crystals melted together. This leads to lower manufacturing costs but also results in slightly lower efficiency, typically around 13-16%.

Pros:

- Lower Cost: Generally less expensive to produce than monocrystalline panels, making them a more budget-friendly option.

- Good Environmental Performance: They have a lower carbon footprint during manufacturing.

Cons:

- Lower Efficiency: While still effective, they do not convert sunlight to energy as efficiently as monocrystalline panels.

- Aesthetic Limitations: The bluish hue and less uniform appearance may be less visually appealing for some buyers.

Application Impact:

These panels are well-suited for large-scale solar farms where space is not an issue. Their lower cost makes them an attractive option for projects with tighter budgets.

Thin-Film Solar Cells

Properties:

Thin-film solar cells are made by depositing one or more thin layers of photovoltaic material onto a substrate. They are lightweight and flexible.

Pros:

- Versatility: Their flexibility allows for installation on a variety of surfaces, including curved ones.

- Performance in Low Light: They tend to perform better in low-light conditions and high temperatures compared to crystalline panels.

Cons:

- Lower Efficiency: They generally have a lower efficiency rate (around 10-12%), requiring more space for the same power output.

- Shorter Lifespan: Typically, they have a shorter lifespan (10-20 years) compared to crystalline panels.

Application Impact:

Thin-film panels are ideal for applications where weight and flexibility are crucial, such as on rooftops with structural constraints or in portable solar solutions.

Bifacial Solar Cells

Properties:

Bifacial solar cells can capture sunlight from both sides, typically using transparent backsheets or glass. This design allows for increased energy production.

Pros:

- Increased Energy Yield: They can achieve higher energy output by utilizing reflected light from the ground or surrounding surfaces.

- Durability: Often built with glass on both sides, they are more resistant to environmental damage.

Cons:

- Higher Initial Investment: The advanced technology and materials can result in higher upfront costs.

- Site-Specific Performance: Their efficiency is highly dependent on installation conditions, such as the albedo of the surface beneath.

Application Impact:

Bifacial panels are particularly effective in environments with high reflectivity (like snow or sand) and are well-suited for large commercial installations.

Summary Table

In summary, the choice of material for solar panels significantly impacts performance, cost, and application suitability. By understanding the specific properties and trade-offs associated with each option, international B2B buyers can make better-informed decisions tailored to their project needs.

In-depth Look: Manufacturing Processes and Quality Assurance for solar panel

The manufacturing process of solar panels is a sophisticated endeavor that combines advanced technology, precision engineering, and stringent quality control measures. For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these processes and the associated quality assurance protocols is crucial for making informed purchasing decisions.

Manufacturing Process of Solar Panels

The solar panel manufacturing process can be broken down into several key stages, each employing specific techniques to ensure the production of high-quality photovoltaic (PV) modules.

1. Silicon Production

The first step involves the extraction of silicon, which is the primary raw material used in solar cells. Silicon is derived from silica, which is found in sand. The production process typically includes:

- Purification of Silica: This involves heating silica in an electric arc furnace to produce metallurgical-grade silicon.

- Conversion to Solar-Grade Silicon: The metallurgical-grade silicon is then further refined through the Siemens process or other methods, resulting in solar-grade silicon with a purity of 99.9999%.

2. Wafer Production

Once silicon is purified, it is transformed into wafers through a series of steps:

- Ingot Formation: The purified silicon is melted and crystallized into cylindrical ingots. These ingots are then sliced into thin wafers using diamond wire saws.

- Wafer Treatment: The sliced wafers undergo treatments to remove saw damage and to prepare the surface for doping.

3. Doping

Doping is the process of adding impurities to silicon wafers to create p-type and n-type semiconductors, essential for the photovoltaic effect. Common dopants include phosphorus (n-type) and boron (p-type).

4. Cell Manufacturing

The doped wafers are then converted into solar cells through various techniques:

- Texturing: This step involves etching the surface of the wafers to reduce reflection and increase light absorption.

- Anti-Reflective Coating (ARC): A thin layer of silicon nitride or titanium dioxide is applied to minimize reflection and enhance efficiency.

- Metallization: Fine silver or aluminum lines are printed on the surface of the cells to collect and transport the generated electricity.

5. Module Assembly

The final stage in the manufacturing process is module assembly:

- Cell Interconnection: Individual solar cells are connected in series and parallel configurations to form a solar panel.

- Encapsulation: The cells are sandwiched between protective layers, usually made of ethylene-vinyl acetate (EVA) and tempered glass, ensuring durability and protection from environmental factors.

- Framing: Aluminum frames are added for structural integrity, allowing for easy installation and handling.

Quality Assurance in Solar Panel Manufacturing

Quality assurance (QA) is a critical aspect of solar panel production, ensuring that the final products meet international standards and buyer specifications. Several quality control (QC) checkpoints and testing methods are employed throughout the manufacturing process.

Illustrative Image (Source: Google Search)

International Standards

Adhering to international standards is vital for ensuring product quality and safety. Some key standards relevant to solar panel manufacturing include:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- IEC 61215: This standard specifies the requirements for the design qualification and type approval of crystalline silicon terrestrial PV modules.

- IEC 61730: This standard addresses the safety of PV modules, covering electrical and mechanical safety requirements.

Quality Control Checkpoints

To maintain high-quality standards, several QC checkpoints are implemented:

- Incoming Quality Control (IQC): At this stage, raw materials such as silicon and glass are inspected for quality and compliance with specifications before being used in production.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, various checks are performed to monitor each stage. This includes checking the uniformity of doping, the integrity of the anti-reflective coating, and the precision of cell interconnections.

- Final Quality Control (FQC): Before shipping, finished solar panels undergo comprehensive testing. This includes visual inspections, electrical performance tests, and environmental stress tests to ensure they meet the required standards.

Common Testing Methods

Several testing methods are commonly employed to verify the quality and performance of solar panels:

- Electroluminescence Testing: This non-destructive method allows manufacturers to identify micro-cracks and defects in the solar cells by visualizing the emitted light when a current is applied.

- Thermal Cycling Tests: Panels are subjected to extreme temperature variations to assess their performance and durability under real-world conditions.

- UV Exposure Testing: This simulates long-term exposure to sunlight to evaluate the effects of UV radiation on the materials used in the panels.

Verifying Quality Control

For B2B buyers, verifying the quality control processes of solar panel manufacturers is crucial. Here are actionable steps to ensure that the products meet your standards:

- Request Certification Documentation: Ask manufacturers for copies of their ISO and IEC certifications. This documentation provides assurance of adherence to international standards.

- Visit Manufacturing Facilities: If possible, conduct site visits to observe the manufacturing process and quality control practices firsthand.

- Review Test Reports: Request copies of FQC test reports to evaluate the performance and reliability of the solar panels.

- Engage Third-Party Testing: Consider hiring independent testing organizations to verify the quality and performance of the solar panels before purchase.

By understanding the manufacturing processes and quality assurance measures in solar panel production, international B2B buyers can make informed decisions, ensuring they procure high-quality, reliable solar energy solutions suitable for their markets.

Comprehensive Cost and Pricing Analysis for solar panel Sourcing

Understanding the cost structure and pricing dynamics of solar panels is essential for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. This analysis will delve into the various cost components, price influencers, and provide actionable insights for effective sourcing.

Cost Components

-

Materials

The primary materials used in solar panel manufacturing include silicon, glass, metals (like aluminum), and various electronic components. Silicon, which constitutes a significant portion of the panel, is derived from raw materials that can fluctuate in price based on global supply and demand dynamics. Buyers should monitor trends in material costs, as they can significantly impact the overall price of solar panels. -

Labor

Labor costs can vary widely depending on the region of production. In countries with higher labor costs, such as those in Europe, the manufacturing process may be more expensive compared to countries in Asia or South America. Moreover, skilled labor is required for quality assurance, installation, and maintenance, which can further elevate costs. Understanding local labor markets is critical when evaluating suppliers. -

Overhead

Overhead costs encompass a range of operational expenses, including utilities, facility maintenance, and administrative costs. These expenses can be influenced by local economic conditions, regulatory requirements, and environmental standards. Buyers should inquire about a manufacturer’s overhead structure to better gauge pricing. -

Quality Control (QC)

Quality control is a crucial aspect of solar panel production, ensuring that products meet safety and performance standards. Implementing robust QC processes can incur additional costs, but they are essential for long-term reliability. Buyers should consider manufacturers that prioritize QC, as this can lead to lower maintenance costs and better performance over time. -

Logistics

The logistics of sourcing solar panels involve transportation costs, customs duties, and warehousing. Shipping costs can vary significantly based on the distance from the manufacturer to the buyer, and tariffs may also apply depending on trade agreements. Buyers should evaluate the total logistics costs when considering different suppliers, especially in regions with complex customs regulations.

Price Influencers

Several factors can influence the pricing of solar panels:

-

Volume of Purchase

Larger orders often attract significant discounts. Suppliers may offer tiered pricing based on order size, incentivizing buyers to purchase in bulk. This can lead to considerable savings, particularly for large-scale projects. -

Specifications and Quality

Custom specifications, such as higher efficiency ratings or specific materials, can increase costs. Buyers should balance the need for high-quality products against their budget constraints, ensuring that they are not overpaying for features that may not be necessary for their application. -

Market Conditions

Global market trends, including shifts in energy policies, technological advancements, and economic conditions, can affect solar panel prices. Buyers should stay informed about these trends to make strategic purchasing decisions.

Buyer Tips

-

Negotiation

Effective negotiation can lead to better pricing. Buyers should come prepared with data on market prices, competitor offers, and their own purchasing power. Building a relationship with suppliers can also lead to favorable terms over time. -

Total Cost of Ownership (TCO)

When evaluating solar panel options, consider the Total Cost of Ownership, which includes not only the initial purchase price but also installation, maintenance, and operational costs over the panel’s lifespan. A lower upfront cost may not always translate to savings if the product has higher maintenance or lower efficiency. -

Supplier Evaluation

Conduct thorough due diligence on potential suppliers. Assess their financial stability, production capabilities, and customer reviews. Engaging with suppliers who have a proven track record in quality and reliability can mitigate risks associated with poor performance. -

Local Regulations and Incentives

Familiarize yourself with local regulations and incentives for solar installations. Many regions offer tax credits, rebates, or subsidies that can significantly offset costs. Understanding these can provide additional leverage in negotiations and overall budget planning.

By analyzing these cost components and price influencers, international B2B buyers can make informed decisions when sourcing solar panels, ultimately leading to more sustainable and cost-effective energy solutions.

Spotlight on Potential solar panel Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘solar panel’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence.

Essential Technical Properties and Trade Terminology for solar panel

Understanding the technical properties and trade terminology associated with solar panels is essential for international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe. This knowledge not only aids in making informed purchasing decisions but also enhances negotiation capabilities with suppliers. Below, we delve into critical specifications of solar panels and commonly used industry jargon.

Key Technical Properties of Solar Panels

-

Efficiency:

- Efficiency refers to the percentage of sunlight that a solar panel can convert into usable electricity. Higher efficiency ratings mean more energy output from the same amount of sunlight. Typical efficiencies range from 15% to over 22% for commercial solar panels. Buyers should prioritize efficiency based on their energy needs and available installation space.

-

Power Output:

- This specification indicates the amount of electricity a solar panel can produce under standard test conditions (STC), typically measured in watts (W). Common outputs for residential panels range from 250W to 400W. Understanding power output is crucial for calculating how many panels are needed to meet specific energy demands.

-

Temperature Coefficient:

- The temperature coefficient measures how much a solar panel’s output decreases as temperatures rise. This is expressed as a percentage per degree Celsius. A lower temperature coefficient indicates better performance in hot conditions, which is particularly relevant in regions with high ambient temperatures.

-

Durability and Warranty:

- Solar panels are subject to environmental conditions, making durability an essential factor. Most panels come with a warranty that covers performance and defects, often lasting 25 years. Buyers should review warranty terms carefully to ensure long-term reliability.

-

Type of Solar Cell:

- There are primarily three types of solar cells: monocrystalline, polycrystalline, and thin-film. Monocrystalline panels are known for their high efficiency and space-saving qualities, while polycrystalline panels offer a balance of cost and performance. Thin-film panels are lightweight and flexible but generally have lower efficiency. Understanding these types helps buyers choose based on their specific application.

-

Size and Weight:

- The physical dimensions and weight of solar panels are critical for installation considerations. Standard panels typically measure around 1.6m x 1m (65 inches x 39 inches) and weigh between 18-25 kg (40-55 lbs). Buyers must ensure that their mounting structures can support the panels’ size and weight.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer):

- An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the solar industry, OEMs provide solar panels and components that are sold under different brand names. Understanding OEM relationships can help buyers evaluate product quality and pricing.

-

MOQ (Minimum Order Quantity):

- MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it can affect inventory costs and procurement strategies. Knowing the MOQ can also help buyers negotiate better terms with suppliers.

-

RFQ (Request for Quotation):

- An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. In the solar panel industry, submitting an RFQ can help buyers obtain detailed proposals from multiple vendors, enabling them to compare offers and make informed decisions.

-

PPA (Power Purchase Agreement):

- A PPA is a contract between a buyer and a power producer. It outlines the terms under which the buyer will purchase electricity generated by a solar installation. Understanding PPAs is vital for buyers looking to finance solar projects through third-party ownership models.

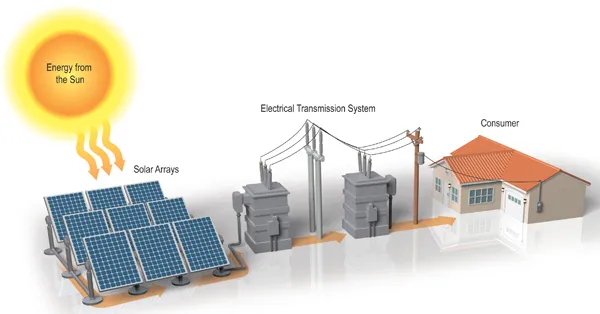

-

Inverter:

- An inverter is a device that converts the direct current (DC) produced by solar panels into alternating current (AC), which is used by most home appliances and the electrical grid. Buyers must consider inverter efficiency and compatibility when selecting solar systems.

-

Grid-Tied vs. Off-Grid Systems:

- Grid-tied systems are connected to the public electricity grid, allowing for net metering and energy exchange. Off-grid systems operate independently, requiring batteries for energy storage. Buyers should assess their energy needs and local regulations to choose the appropriate system type.

By familiarizing themselves with these technical properties and trade terminologies, international B2B buyers can navigate the solar panel market more effectively, ensuring that they make strategic purchasing decisions that align with their energy requirements and business goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the solar panel Sector

The solar panel market has experienced exponential growth in recent years, driven by a combination of technological advancements, government incentives, and increasing awareness of climate change. In 2023, the global solar energy market was valued at approximately $200 billion, with projections suggesting it could exceed $400 billion by 2030. This growth is particularly notable in regions like Africa and South America, where solar energy is increasingly viewed as a viable solution to energy scarcity and reliance on fossil fuels.

Market dynamics are influenced by several key trends. Firstly, the push for renewable energy sources is becoming a central theme in government policies across Europe, Africa, and the Middle East. Countries are implementing ambitious renewable energy targets, driving investments in solar infrastructure. For instance, the European Union aims to achieve a 55% reduction in greenhouse gas emissions by 2030, prompting significant investments in solar technologies.

Additionally, technological innovation is leading to enhanced efficiency and reduced costs for solar panels. The rise of bifacial solar panels, which can capture sunlight from both sides, represents a significant advancement in maximizing energy output. Furthermore, the integration of energy storage solutions, such as lithium-ion batteries, is enabling businesses to harness solar energy more effectively, ensuring power availability even during periods of low sunlight.

For international B2B buyers, understanding these trends is crucial for making informed sourcing decisions. Collaborating with suppliers who are at the forefront of technology and sustainability can provide a competitive edge in this rapidly evolving market.

Sustainability is a critical consideration in the solar panel sector, particularly for B2B buyers looking to align with environmentally responsible practices. The production of solar panels involves several materials, including silicon, silver, and rare earth metals, which can pose ethical and environmental challenges. Buyers are increasingly prioritizing suppliers who adhere to sustainable sourcing practices, ensuring that materials are obtained responsibly and with minimal environmental impact.

The concept of circular economy is gaining traction, urging manufacturers to focus on recycling and reusing materials. For instance, companies are exploring ways to recycle old solar panels to recover valuable materials, which not only reduces waste but also lowers the demand for virgin materials. Additionally, ethical sourcing practices, including fair labor conditions and community engagement, are becoming essential criteria for selecting suppliers.

B2B buyers should seek suppliers with transparent supply chains and certifications that demonstrate their commitment to sustainability, such as ISO 14001 for environmental management. This commitment not only enhances brand reputation but also meets the growing consumer demand for sustainable products.

The solar panel industry has a rich history that reflects the evolution of renewable energy technology. The first photovoltaic (PV) cell was developed in 1954 by Bell Labs, marking the beginning of solar technology as a viable energy source. However, it wasn’t until the oil crisis of the 1970s that significant attention was directed toward solar energy as an alternative to fossil fuels.

Throughout the 1980s and 1990s, advancements in technology and reductions in costs began to make solar panels more accessible. By the early 2000s, government incentives and subsidies propelled the industry further, leading to widespread adoption in residential and commercial sectors. Today, solar energy is recognized as a cornerstone of the global energy transition, with ongoing innovations promising to enhance efficiency, reduce costs, and expand the role of solar energy in the world’s energy mix.

For B2B buyers, understanding this historical context can provide insights into the technological advancements and market dynamics that shape current sourcing strategies, enabling more informed decisions in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of solar panel

-

What criteria should I use to vet solar panel suppliers?

When vetting solar panel suppliers, prioritize their certifications (such as ISO, IEC), production capacity, and years of experience in the industry. Look for suppliers with a proven track record of quality assurance and customer satisfaction. Request references from previous clients and check for any reviews or ratings online. Additionally, ensure that they provide warranties and after-sales support, as these are indicators of reliability and commitment to quality.

Illustrative Image (Source: Google Search)

-

Can solar panels be customized to meet specific requirements?

Yes, many suppliers offer customization options for solar panels to cater to unique project needs. Customizations can include different sizes, power outputs, and aesthetic designs. When discussing customization, provide detailed specifications regarding your energy requirements and installation environment. Collaborate closely with the supplier to ensure that the final product aligns with your operational goals and local regulations.

Illustrative Image (Source: Google Search)

-

What is the minimum order quantity (MOQ) for solar panels?

The MOQ for solar panels can vary significantly between suppliers and may depend on the type and specifications of the panels. Typically, larger orders might qualify for better pricing, while smaller orders may face higher unit costs. Clarify the MOQ during initial discussions and consider negotiating terms if your project requires a smaller quantity. Be aware that some suppliers may offer flexibility in MOQs for first-time buyers or long-term partnerships. -

How can I ensure quality assurance in my solar panel purchases?

To ensure quality assurance, request detailed documentation regarding the manufacturing process, including compliance with international standards. Suppliers should provide test reports and certifications for their products. Additionally, consider implementing a third-party inspection service during production and before shipment to verify that the panels meet your specified criteria. Establishing a clear communication channel with the supplier can also facilitate quality control. -

What logistics considerations should I keep in mind when sourcing solar panels?

Logistics is crucial when sourcing solar panels. Consider the shipping methods and costs, potential import/export duties, and delivery timelines. Assess the supplier’s ability to manage logistics, including packaging to prevent damage during transit. Additionally, evaluate the location of the supplier relative to your project site, as this can impact shipping costs and lead times. Establish clear logistics terms in your contract to avoid misunderstandings. -

What are the typical lead times for solar panel orders?

Lead times for solar panel orders can range from a few weeks to several months, depending on the supplier’s production capacity and your order size. For customized panels, lead times may extend further. Always inquire about estimated lead times during the negotiation phase and factor these into your project timeline. It’s advisable to place orders well in advance, especially if your project is tied to specific deadlines or seasonal considerations. -

How do warranties work for solar panels?

Warranties for solar panels typically include product warranties (covering defects) and performance warranties (guaranteeing energy output). Product warranties generally last between 10 to 25 years, while performance warranties often promise 80% of rated output after 25 years. Be sure to review the warranty terms carefully, including any conditions that may void the warranty. Understanding warranty coverage is essential for long-term investment protection and peace of mind. -

What should I know about after-sales support from suppliers?

After-sales support is critical for the successful operation of solar panels. Ensure that the supplier offers robust technical support, troubleshooting assistance, and maintenance services. Inquire about the availability of spare parts and the process for obtaining them. Establishing a clear line of communication for after-sales inquiries will help resolve issues promptly. A supplier with a strong support system can enhance the longevity and efficiency of your solar energy systems.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide is for informational and educational purposes only. It does not constitute professional procurement, financial, or legal advice.

While we have made every effort to ensure accuracy, we are not responsible for any errors or omissions. Market conditions and company details are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions.

Strategic Sourcing Conclusion and Outlook for solar panel

In the evolving landscape of solar panel procurement, international B2B buyers must prioritize strategic sourcing to navigate market complexities and capitalize on opportunities. Key takeaways include the importance of understanding regional market dynamics, leveraging competitive pricing, and fostering relationships with suppliers to ensure reliability and quality. By adopting a comprehensive sourcing strategy, businesses can not only reduce costs but also enhance their sustainability initiatives, aligning with global trends towards renewable energy.

As solar technology continues to advance, the potential for innovation in supply chain practices expands. Buyers should stay informed about emerging trends, such as the integration of smart technologies and the push for more sustainable materials. This proactive approach will not only strengthen procurement strategies but also position companies as leaders in the renewable energy sector.

Moving forward, it is crucial for B2B buyers in Africa, South America, the Middle East, and Europe to engage with suppliers, attend industry conferences, and participate in collaborative networks. By doing so, they can unlock new opportunities, drive efficiencies, and contribute to a more sustainable future. Embrace strategic sourcing today to navigate tomorrow’s energy landscape effectively.